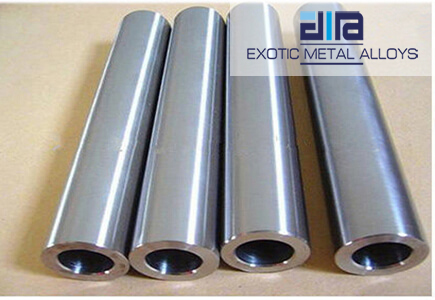

Monel 400 Pipes & Tubes

Exotic Metal Alloys is offers Monel Alloy 400 Pipes, where in a way to accomplish total consumer loyalty, we ideal convey the transfers from our end with the assistance of our wide circulation arrange. Monel 400 Seamless Pipes is a nickel – copper combination with high quality and astounding consumption obstruction in a scope of media including ocean water, hydrofluoric corrosive, sulfuric corrosive, and antacids.

Monel 400 Welded Pipes is likewise a strong – arrangement nickel – copper amalgam that is impervious to erosion in numerous situations. Monel 400 EFW Pipes is notable for its high quality and erosion safe properties. In the interim, these Monel 400 ERW Pipes are additionally being offered in various sizes and shapes to our clients.

Monel 400 Round Pipes (UNS N04400) is impervious to the ocean water consumption just as to an assortment of acids and other destructive media. Monel 400 Pipes, any of a gathering of nickel – copper compounds, contains around 66 percent of nickel and 31.5 percent of copper, with modest quantities of iron, manganese, carbon, and silicon.

Monel 400 Pipes are nickel – base combinations that contain between 29 percent and 33 percent of copper. Monel 400 Pipes are more grounded than unadulterated nickel and impervious to consumption by numerous specialists, including quickly streaming seawater. These Monel 400 Pipes has high quality and strength over a wide temperature run and magnificent protection from numerous destructive situations.

Specifications of Monel 400 Pipes & Tubes

| Specifications | : | ASTM B 165 ASME SB 165 / ASTM B 725 ASME SB 725 |

| Dimensions | : | ASTM, ASME and API |

| Size | : | 15″NB TO 150″NB IN |

| Specialized in | : | Large Diameter Size |

| Range | : | 6.35 mm OD upto 254 mm OD in 0.6 TO 20 mm thickness. |

| Type | : | Seamless / ERW / Welded / Fabricated |

| Form | : | Round, Hydraulic Etc |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Monel 400 | N04400 | 2.4360 | NU-30M | NiCu30Fe | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 |

Chemical Composition Of Monel 400 Pipes & Tubes

| Monel 400 | Ni | C | Al | Mn | Si | Fe | Cu | S | Co | Cr |

| 63.0 min | 0.3 max | 0.50 max | 2.0 max | 0.5 max | 1.0 – 2.5 | 28.0 – 34.0 | 0.02 max | – | – |

Mechanical Properties Of Monel 400 Pipes & Tubes

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 35,000 , MPa – 240 | Psi – 80,000 , MPa – 550 | 40 % |

Other Types Of Monel 400 Pipes & Tubes

| Monel Alloy 400 Tubing | UNS N04400 Alloy Pipes | Monel 400 Seamless Pipes |

| 400 Monel Electric Fusion Welding Pipes | 400 Alloy Instrumentation Tubes | Monel 400 Capillary Tube |

| Alloy 400 ERW Pipes | Monel 400 Rectangular Tubes | Monel Alloy 400 Cold Rolled Coiled Tubing |

| Alloy 400 Welded Tubes | 400® Monel Seamless Tubes | 400 Alloy Welded Pipes |

| 400 Alloy Fabricated Pipes | Monel 400 Fabricated Tubes | Monel 400 EFW Round Pipes |

| Monel 400 Rectangular Pipes | Alloy 400 Large Diameter Fabricated Tubes | Alloy 400 Polished Pipe |

| Monel 400 Pipes | Monel 400 Tubes | Alloy 400 Piping |

Monel 400 Pipes & Tubes, Monel 400 Pipes & Tubes Exporters, Monel 400 Pipes & Tubes Suppliers, Monel 400 Pipes & Tubes Importers, Monel 400 Pipes & Tubes Stockists

Monel 400 Pipes & Tubes In Mumbai, Monel 400 Pipes & Tubes Exporters In Mumbai, Monel 400 Pipes & Tubes Suppliers In Mumbai, Monel 400 Pipes & Tubes Importers In Mumbai, Monel 400 Pipes & Tubes Stockists In Mumbai.

Monel 400 Pipes & Tubes In India, Monel 400 Pipes & Tubes Exporters In India, Monel 400 Pipes & Tubes Suppliers In India, Monel 400 Pipes & Tubes Importers In India, Monel 400 Pipes & Tubes Stockists In India

UNS N04400 Monel 400 Tubes Suppliers, 400 Alloy EFW Fabricated Pipes, DIN 2.4360 Monel 400 ERW Pipes, Monel Alloy 400 Pipes Exporters in India. UNS N04400 Monel Nicorros Welded Tubes, Nickelvac 400 Seamless Round Pipes Worldwide Distributors, Alloy 400 Seamless Tubes Exporters, Monel Alloy 400® Welded Pipes Stockholders in India. Monel 400 Square Tube Stockists, 400 Alloy Large Diameter Fabricated Tubes, Monel 400 Rectangular Pipes Dealers, WNR 2.4360 Monel 400 Polished Pipe Suppliers in India.

- Domestic Area

- Our Export