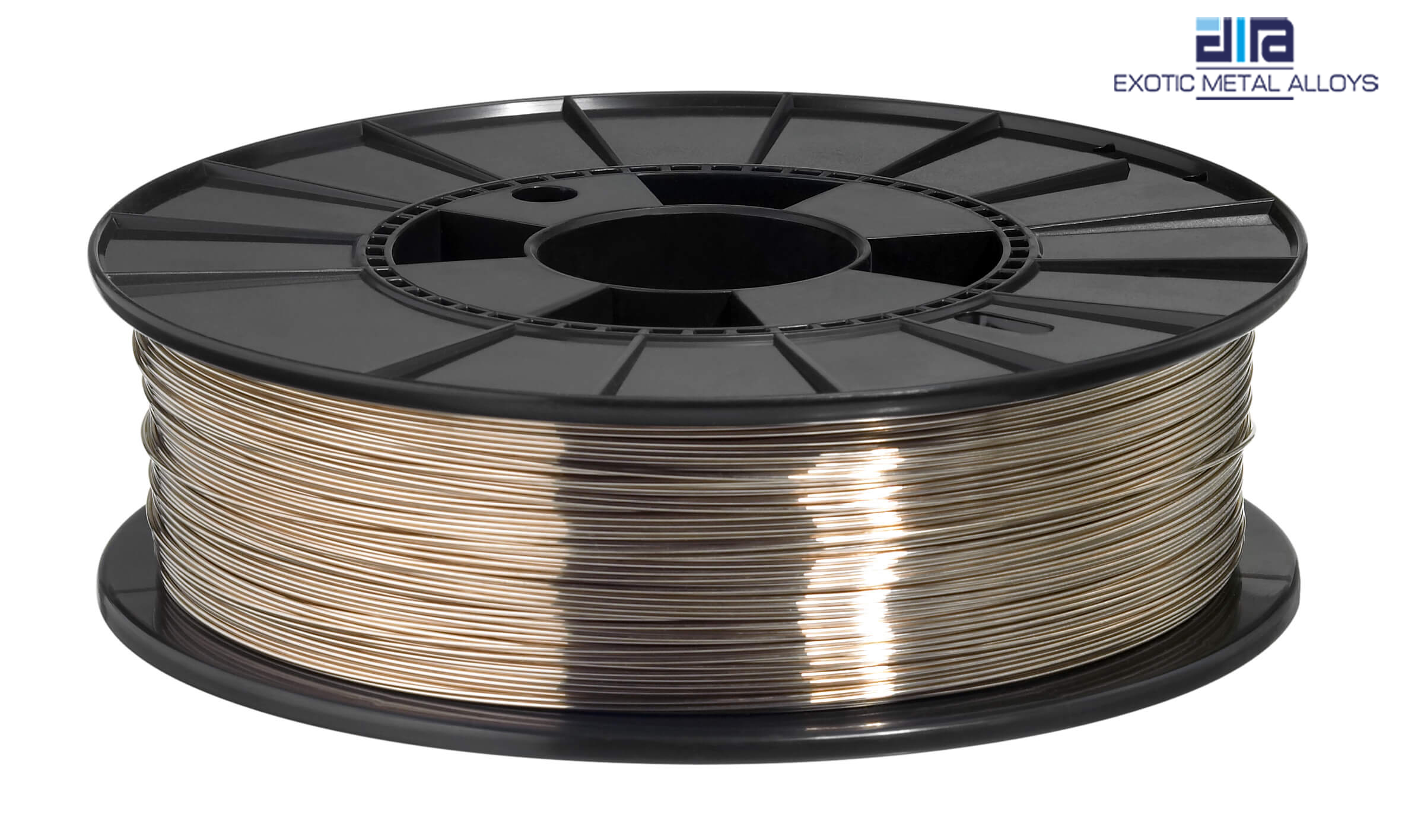

Incoloy 825 Wires

There are different providers you will see accessible offering the wide complete dimension of Incoloy bars. To make your putting referencing task less confusing, we will get a handle on you to approach Padmavati Steel & Engg.Co.. Extremely, this is of the best business that is working in an unrivaled manner in offering high check of both respect included affiliations and plans after affiliations.

Notwithstanding, giving the high bore of Incoloy 825 wires are their central target. This breezes up conceivable precisely when they are utilizing the choice idea of foul materials, current, and cutting edge improvement. This had helped the makers in offering the smart thought of things to regard supports.

The detail of Incoloy 825 wires is ASME SB 166, ASTM B 166. The piece of the thing is AWCI/ANSI-01-1992 and RRW 360 and ASTM E 2016-11. Long, the thing is open from 100 mm to 6000 mm. The estimation of the thing is 10 mm to 100 mm. It watches out for essential expert in filler wire, welding wire, anode wire, and circle wire.

We are giving more significance to the thing test as it guarantees us about whether there is any need in thing quality. The testing performed in the business is the hardness test, setting obstruction test, spread granular breaking down test, positive material certain affirmation test, and so on.

Certainly when a provider is passing on the thing, they pack the thing Incoloy 825 wire utilizing wooden beds, wooden holders, wooden boxes, and so forth to guarantee that thing gets beguiling accomplishment and prosperity tries from violence and remarkable harms.

Specifications of Incoloy 825 Wires

| Specifications | : | ASTM / ASME B425 / SB425 |

| Dimensions | : | ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360 |

| Length | : | 100 mm TO 6000 mm |

| Diameter | : | 0.01 mm To 200 mm |

| Specialize | : | Filler Wire, Coil Wire |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | ЭП703 | NFE30C20DUM | NiCr21Mo | XH38BT |

Chemical Composition Of Incoloy 825 Wires

| Element | Incoloy 825 |

| C | 0.05 max |

| Mn | 1.00 max |

| Si | 0.5 max |

| S | 0.03 max |

| Cu | 1.50 – 3.00 |

| Fe | 22.00 min |

| Ni | 38 -46 |

| Cr | 19.50 – 23.50 |

| Al | 0.02 max |

| Ti | 0.06 – 1.20 |

Mechanical Properties Of Incoloy 825 Wires

| Element | Incoloy 825 |

| Density | 8.14 g/cm3 |

| Melting Point | 1400 °C (2550 °F) |

| Tensile Strength | Psi – 80,000 , MPa – 550 |

| Yield Strength (0.2%Offset) | Psi – 32,000 , MPa – 220 |

| Elongation | 30 % |

Inconel 825 Wire, Inconel 825 Wire Exporters, Inconel 825 Wire Suppliers, Inconel 825 Wire Importers, Inconel 825 Wire Stockists

Inconel 825 Wire In Mumbai, Inconel 825 Wire Exporters In Mumbai, Inconel 825 Wire Suppliers In Mumbai, Inconel 825 Wire Importers In Mumbai, Inconel 825 Wire Stockists In Mumbai

Inconel 825 Wire In India, Inconel 825 Wire Exporters In India, Inconel 825 Wire Suppliers In India, Inconel 825 Wire Importers In India, Inconel 825 Wire Stockists In India

Suppliers And Exporters Of 825 Incoloy Coil Wire, Alloy 825 Wire, 825 Incoloy Wire, ASTM B425 Incoloy Wire, Incoloy GOST ЭП703 Wire In Mumbai, India. Incoloy UNS N08825 Bright Wire, Incoloy WERKSTOFF NR. 2.4858 Wire, Exporters Of AMS 5742 825 Incoloy Wire Manufacturer In India, Manufacturer Of ASTM SB425 Incoloy 825 Wire, Incoloy 825 Wire Bobbin, Incoloy Alloy 825 Wire Rope, 825 Incoloy Alloy Wire Exporter In India. Tig Wire Welding, Mig Wire Welding, Tig Welding Spool, Mig Welding Spool.

- Domestic Area

- Our Export