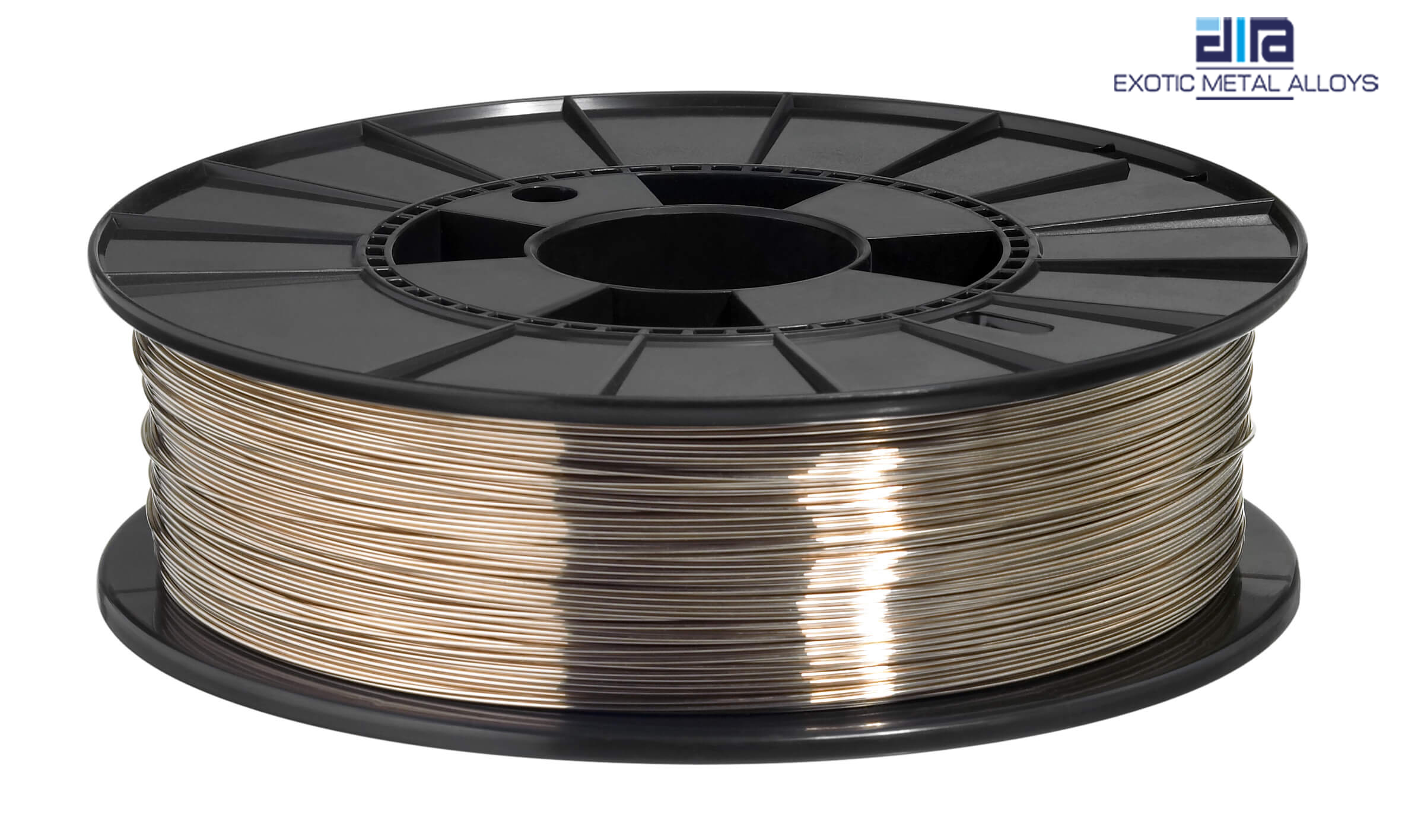

Inconel 600 Wires

Inconel 600 is a mix containing nickel and chromium portions with oxidation obstruction, sustenance usage hindrance and high inflexible nature at high and raised temperature. It is particularly impervious to part and stress usage because of the closeness of nickel content.

While utilizing this blend no age solidifying procedure is required, it is invigorated and set through the contamination work. It can even work through cryogenic temperature. There are two or three things made utilizing this blend, where Inconel 600 wire is widely utilized and observable because of its astonishing properties and highlights.

We are propelling a wide degree of Inconel wire to meet the basics and essentials of the application. These wires are attested and made utilizing the best thought of grungy material and cutting edge advancement. These wires are known best for its strength, usage obstruction, and quality and impervious to oxidation. These wires join both national and in general nuances and checks including ASTM B166M, AMS 5665, BS 3075 NA14 and other overall principles.

Inconel 600 wire is open in various structures, sizes as shown by the fundamental and requesting of clients. At the time making, these wires continue running over different tests and reviews like flaring test, smoothing test, radiography test and untouchable examination. Not just this, these wires are experienced different conditions and temperature to check the solidness and limit.

Specifications of Inconel 600 Wires

| Specifications | : | ASTM B166 ASME SB166 |

| Dimensions | : | ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360 |

| Length | : | 100 mm TO 6000 mm |

| Diameter | : | 0.01 mm To 200 mm |

| Specialize | : | Filler Wire, Coil Wire |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Chemical Composition Of Inconel 600 Wires

| Element | Inconel 600 |

| C | 0.15 max |

| Mn | 1.00 max |

| Si | 0.50 max |

| S | 0.015max |

| Cu | 0.50 max |

| Fe | 6 – 10 |

| Ni | 72.00 min |

| Cr | 14 – 17 |

Mechanical Properties Of Inconel 600 Wires

| Element | Inconel 600 |

| Density | 8.47 g/cm3 |

| Melting Point | 1413 °C (2580 °F) |

| Tensile Strength | Psi – 95,000 , MPa – 655 |

| Yield Strength (0.2%Offset) | Psi – 45,000 , MPa – 310 |

| Elongation | 40 % |

Inconel 600 Wire, Inconel 600 Wire Exporters, Inconel 600 Wire Suppliers, Inconel 600 Wire Importers, Inconel 600 Wire Stockists

Inconel 600 Wire In Mumbai, Inconel 600 Wire Exporters In Mumbai, Inconel 600 Wire Suppliers In Mumbai, Inconel 600 Wire Importers In Mumbai, Inconel 600 Wire Stockists In Mumbai.

Inconel 600 Wire In India, Inconel 600 Wire Exporters In India, Inconel 600 Wire Suppliers In India, Inconel 600 Wire Importers In India, Inconel 600 Wire Stockists In India

Inconel 600 Wire Stockists, 600 Inconel Coil Wire, Alloy 600 Wire, 600 Inconel Filler Wire, ASTM B166 Inconel Wire In Mumbai, India. Inconel UNS N06600 Bright Wire, Exporters Of ASTM SB166 600 Inconel Wire, Inconel WERKSTOFF NR. 2.4816 Wire In India Inconel 600 Wire Bobbin, Inconel Alloy 600 Wire Rope, ASME SB166 Inconel 600 Wire, 600 Inconel Alloy Wire Exporter, In India. Tig Wire Welding, Mig Wire Welding, Tig Welding Spool, Mig Welding Spool.

- Domestic Area

- Our Export