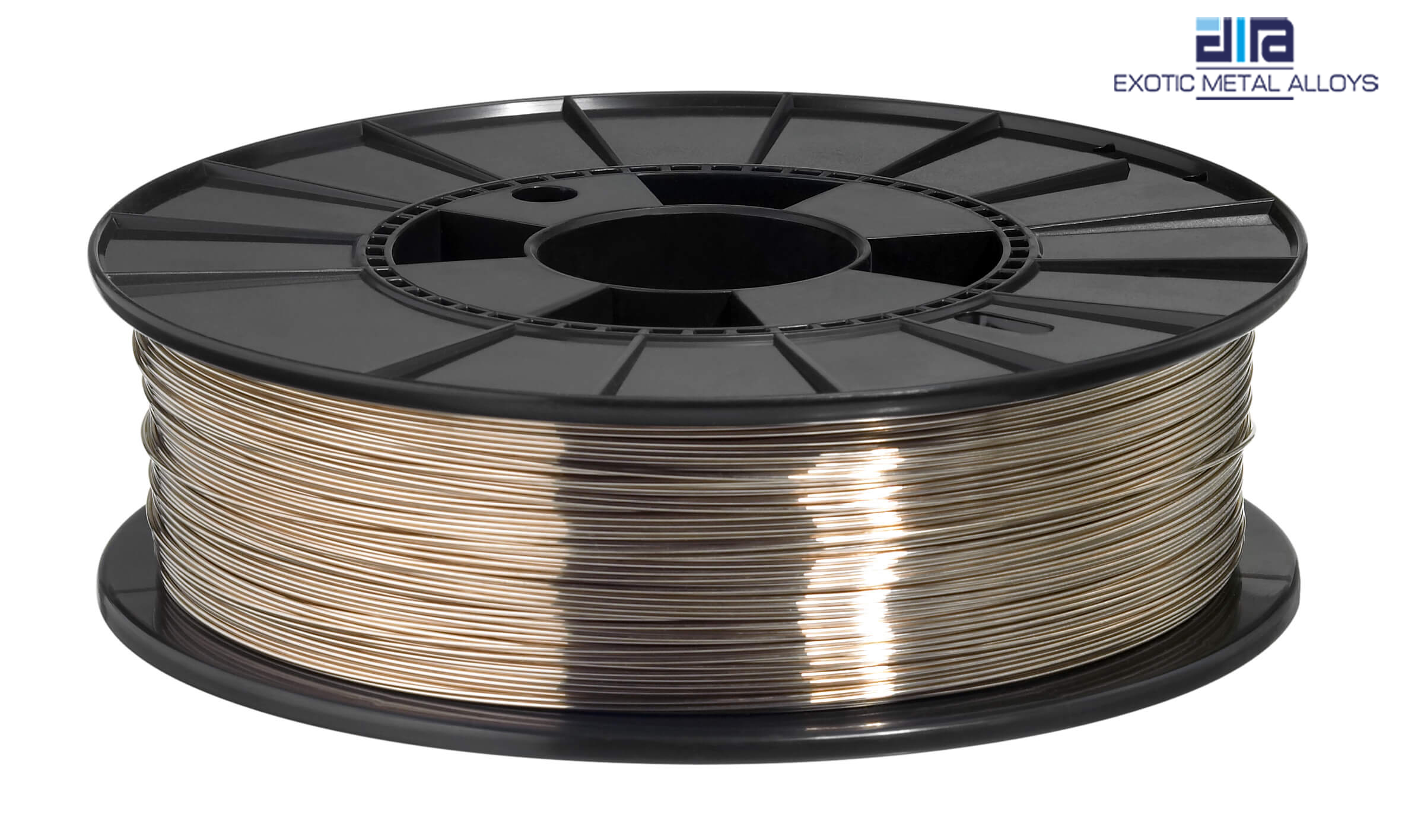

Inconel 625 Wires

Inconel 625 wire is made in square, level and in clearly limited wires. When you use these wires, the two most basic things you will notice are scaling at high temperature and affirmation from oxidation. These two things make wires customary that is the reason they are generally used for high-temperature affiliations.

These wires can purpose of actuality withstand in ridiculous temperature and condition without losing their quality. The high degree of molybdenum used in this blend makes it strong and insusceptible to setting. There are a couple of employments that usage these wires.

If you are examining for the standard and acknowledged producers than Sparsh Impex is a victor among the best assembling affiliations. It offers its clients and customers a high proportion of wires that are made using unequivocally bleeding edge headway and general quality standard terrible material. Each and every material used for accumulating these wires is all around tried and explored. Not simply this, these wires are made under the supervision of colossal worth specialists.

Inconel 625 wire, they interlace national and general subtleties and measures including ASTM B166 and ASME SB166. These wires are even open to customers in different structures like wire circle, wire turn, dazzling wire and filler wire. There are a couple of tests done to guarantee that everything is of good quality and offer the best execution. These wires are offered to customers in different structures as appeared by their need and mentioning. Also, they are pack in holders or wooden boxes to baffle rusting.

Specifications of Inconel 625 Wires

| Specifications | : | ASTM B166 ASME SB166 |

| Dimensions | : | ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360 |

| Length | : | 100 mm TO 6000 mm |

| Diameter | : | 0.01 mm To 200 mm |

| Specialize | : | Filler Wire, Coil Wire |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

Chemical Composition Of Inconel 625 Wires

| Element | Inconel 625 |

| C | 0.10 max |

| Mn | 0.50 max |

| Si | 0.50 max |

| S | 0.015 max |

| Cu | - |

| Fe | 5.0 max |

| Ni | 58.0 min |

| Cr | 20 - 23 |

Mechanical Properties Of Inconel 625 Wires

| Element | Inconel 625 |

| Density | 8.4 g/cm3 |

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 1,35,000 , MPa – 930 |

| Yield Strength (0.2%Offset) | Psi – 75,000 , MPa – 517 |

| Elongation | 42.5 % |

Inconel 625 Wire, Inconel 625 Wire Exporters, Inconel 625 Wire Suppliers, Inconel 625 Wire Importers, Inconel 625 Wire Stockists

Inconel 625 Wire In Mumbai, Inconel 625 Wire Exporters In Mumbai, Inconel 625 Wire Suppliers In Mumbai, Inconel 625 Wire Importers In Mumbai, Inconel 625 Wire Stockists In Mumbai.

Inconel 625 Wire In India, Inconel 625 Wire Exporters In India, Inconel 625 Wire Suppliers In India, Inconel 625 Wire Importers In India, Inconel 625 Wire Stockists In India

Inconel 625 Coil Wire, Alloy 625 Wire, 625 Inconel Wire, ASTM B166 Inconel Wire, Inconel GOST ХН75МБТЮ Wire Suppliers And Exporters In Mumbai, India. Inconel UNS N06625 Bright Wire, Exporters Of ASTM SB166 625 Inconel Wire, Inconel WERKSTOFF NR. 2.4856 Wire In India. ASME SB166 Inconel 625 Wire, Inconel 625 Wire Bobbin, Inconel Alloy 625 Wire Rope, 625 Inconel Alloy Wire Exporter, In India. Tig Wire Welding, Mig Wire Welding, Tig Welding Spool, Mig Welding Spool.

- Domestic Area

- Our Export

.jpg)