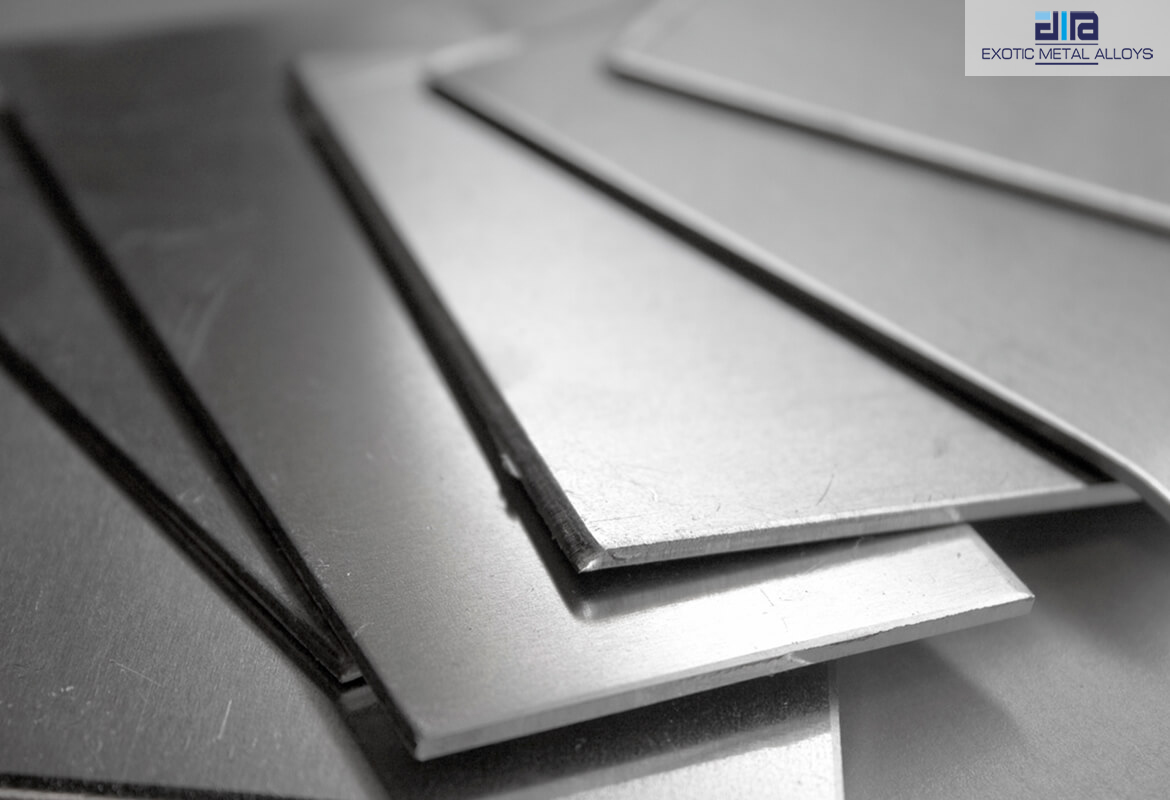

Inconel 601 Sheets & Plates

Inconel 601 is a Ni-Cr mix utilized for applications that require security from use and warmth. Inconel 601 compound makes by virtue of its security from high temperature oxidation, remaining impervious to oxidation through 2200° F. Inconel 601 builds up an emphatically fan oxide scale which limits spalling even under states of ensured warm cycling. This nickel composite has staggering high temperature quality.

It moreover holds it's versatility after a goliath level of association introduction. It has impossible confirmation from fluid isolating, high mechanical quality, and is advantageously framed, machined and welded. Inconel 601's applications are progression overseeing, warm arranging, , sullying control, flying motors, and power age. In any case, Inconel 601 can't be utilized in sulfur bearing conditions.

We offers a wide amassing of Inconel 601 Sheets Plates, which are totally fitting for fascinating purposes with regards to marvelous undertakings. Inconel 601 Plates is noteworthy for mix progress gear, for example, process radiators, condenser tubes and combustor districts. Inconel 601 Slatting Coils has stunning security from watery use. Inconel 601 Perforated Coils has mind boggling hot isolating limitation under oxidizing conditions.

Inconel 601 Coils moves in setting on its affirmation from taking off temperature oxidation, where we additionally offer the indistinct at industry driving costs. Compound 601 Slatting Coils has surprising oxidation limitation in addition has unimaginable security from carburizing at any rate ought not be utilized in show containing sulfur content. Composite 601 Perforated Coils must be cooled as smart as conceivable through the range 1400 Degree F to 1000 Degree F. Nickel-Alloy 601 Sheets is routinely utilized for warm reactors in vapor technique of oil motors.

Nickel-Alloy 601 Plates is what's increasingly utilized for combustor parts and drive mastermind bolsters in apparatus for nitric hurting age. These Nickel-Alloy 601 Coils are in addition utilized in cases, plate, and mechanical social events for warmth – treating gear. Enormous demulcents Inconel UNS N06601 Sheets Plates are utilized for tapping, infiltrating, underwriting or debilitating. In the mean time, these Alloy 601 Plates are in like way being offered in various sizes and shapes to our clients.

Specifications of Inconel 601 Sheets & Plates

Specifications : ASTM / ASME SB 168

Size : 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm

Thickness : 0.01 mm to 250 mmThk

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange)

Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

| Standard | Inconel 601 |

| UNS | N06601 |

| DIN | 17751 |

| ISO | 6207 |

| WERKSTOFF NR. | 2.4851 |

Chemical Composition Of Inconel 601 Sheets & Plates

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.00 max | 0.50 max | 0.015max | 1.00 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

Mechanical Properties Of Inconel 601 Sheets & Plates

| Element | Inconel 601 |

| Density | 8.1 g/cm3 |

| Melting Point | 1411 °C (2571 °F) |

| Tensile Strength | Psi – 80,000 , MPa – 550 |

| Yield Strength (0.2%Offset) | Psi – 30,000 , MPa – 205 |

| Elongation | 30 % |

Other Types Of Inconel 601 Sheets & Plates

| Inconel 601® Sheets | Inconel 601 Plates | Inconel Alloy 601 Coils |

| Inconel 601 Hot Rolled Plate (HR) | Alloy 601® Cold Rolled Sheet (CR) | N06601 Alloy 601 Circle |

| 601® Inconel Slatting Coil | DIN 2.4851 Alloy Thin Sheet | Inconel 601® Strips |

| Inconel Alloy 601 Shim Sheet | UNS N06601 Alloy Plate | Inconel 601® Flats |

| Alloy 601 Plain Sheet | 601® Inconel Blank (Circle) | 601 Alloy Foils |

| N06601 Alloy Rolls | Inconel 601 Perforated Sheet | Inconel 601® Strip |

| UNS N06601 Alloy 601® Shim Sheet | Inconel 601® Polished Plates | Inconel Alloy 601 Polished Sheets |

Inconel 601 Sheets & Plates, Inconel 601 Sheets & Plates Exporters, Inconel 601 Sheets & Plates Suppliers, Inconel 601 Sheets & Plates Importers, Inconel 601 Sheets & Plates Stockists

Inconel 601 Sheets & Plates In Mumbai, Inconel 601 Sheets & Plates Exporters In Mumbai, Inconel 601 Sheets & Plates Suppliers In Mumbai, Inconel 601 Sheets & Plates Importers In Mumbai, Inconel 601 Sheets & Plates Stockists In Mumbai.

Inconel 601 Sheets & Plates In India, Inconel 601 Sheets & Plates Exporters In India, Inconel 601 Sheets & Plates Suppliers In India, Inconel 601 Sheets & Plates Importers In India, Inconel 601 Sheets & Plates Stockists In India

DIN 2.4851 Inconel 601 Plates, Inconel 601 Perforated Sheet Suppliers, Alloy 601 Thin Sheet, UNS N06601 Inconel Alloy 601 Sheets Exporters, 601 Alloy Coils Distributors in India. Alloy 601 Plate, Inconel Ferrochronin 601 Plain Sheet Worldwide Exporters, Nickelvac 601 Shim Sheets Stockholders, N06601 Inconel Alloy 601 Strips, Alloy 601 Slatting Coil Dealers in India. ASTM A168 Alloy 601 Inconel Strips, Inconel 601 Hot Rolled Plate (HR) Stockists, 601 Alloy Cold Rolled Sheet (CR) Dealers, Inconel 601 Polished Plates, WNR 2.4851 Inconel 601 Circle Suppliers in India.

- Domestic Area

- Our Export