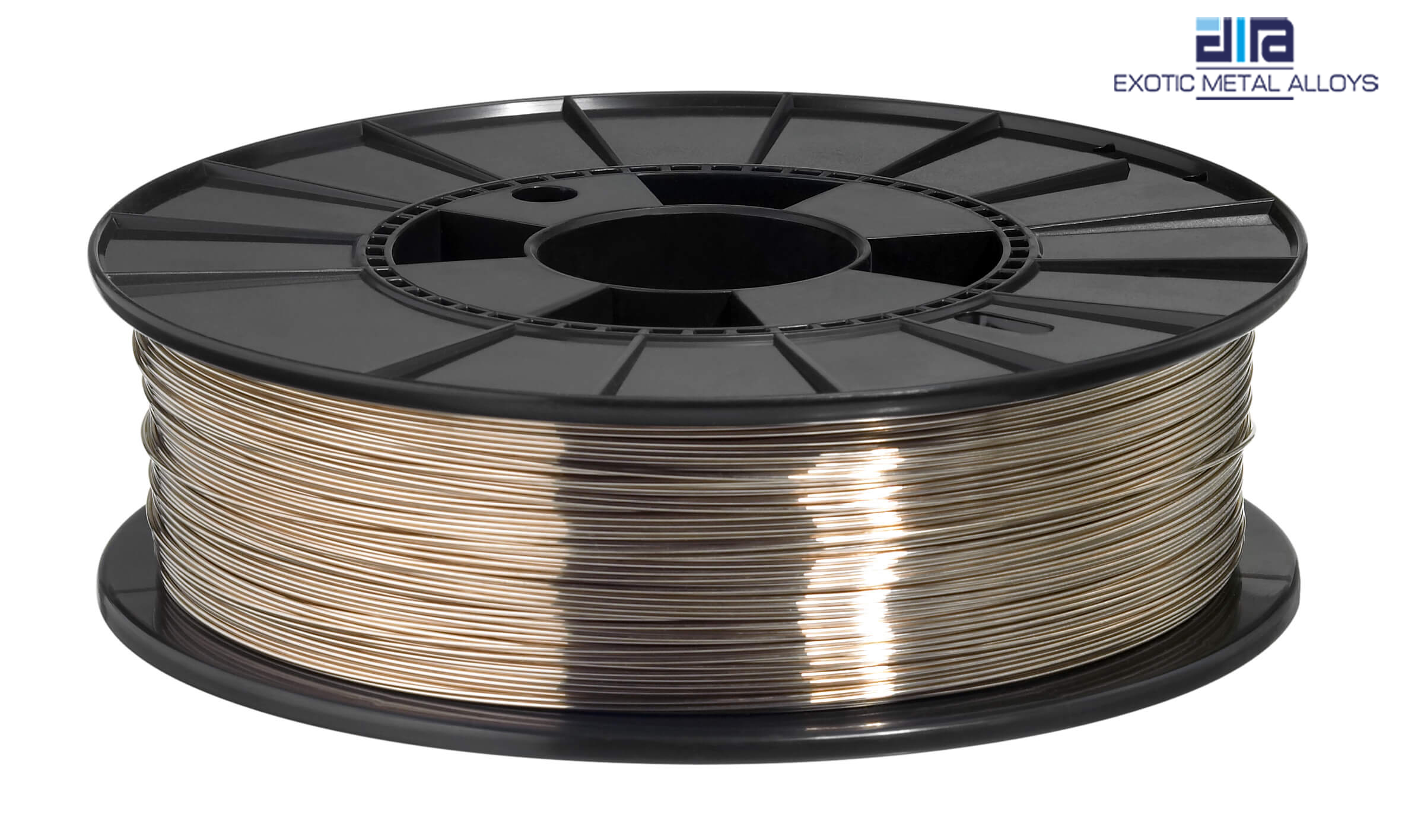

Monel K500 Wires

Monel K500 wire is on an amazingly fundamental estimation a copper and nickel-based blend that in a general sense joins high check and use get and has unmistakable included focal centers like hardness and versatility. More likely than not on the planet, the advancement in the quality, in like path as hardness, is on a key estimation the eventual outcome of precipitation that is broadened due to the development of aluminum and titanium.

In fact, clearly, we talk about Monel K500 wire, these wires are known best for their high adaptability falling apart deterrent, flexibility, and quality. There are evident driving creators who age the best idea of wires.

If you are isolating for the right maker, by then we would fortify you to pick Padmavati Steel & Engg.Co. is the right option for you. They are the chief makers who give their customers best and high check of wires in different shapes, sizes and structures as per support their potential favored position and application essential. In like way, the extreme material and various parts added to Monel composite help wires to withstand as a top priority blowing condition and temperature.

These wires meet both national and everything considered choices and standards including ASTM B865 and ASME SB865 models. The bits of these wires join ANSI/AWCI checks. The length of the wires shifts from 100mm to 6000mm in any case wires separate transversely over changes from 10mm to 100mm. Likewise, these wires are open in different structures like circle wire, filer wire, anode wire and welding wire.

Specifications of Monel K500 Wires

| Specifications | : | ASTM B865 ASME SB865 |

| Dimensions | : | ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360 |

| Length | : | 100 mm TO 6000 mm |

| Diameter | : | 0.01 mm To 200 mm |

| Specialize | : | Filler Wire, Coil Wire, Electrode Wire, Welding Wire. |

| STANDARD | WERKSTOFF NR. | UNS |

| Monel K500 | 2.4375 | N05500 |

Chemical Composition Of Monel K500 Wires

| Element | Monel K500 |

| C | 0.25 max |

| Mn | 1.5 max |

| Si | 0.5 max |

| S | 0.010 max |

| Cu | 27 – 33 |

| Fe | 0.5 – 2 |

| Ni | 63.00 min |

Mechanical Properties Of Monel K500 Wires

| Element | Monel K500 |

| Density | 8.44 g/cm3 |

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 160000 , MPa – 1100 |

| Yield Strength (0.2%Offset) | Psi – 115000 , MPa – 790 |

| Elongation | 20 % |

Monel K500 Wire, Monel K500 Wire Exporters, Monel K500 Wire Suppliers, Monel K500 Wire Importers, Monel K500 Wire Stockists

Monel K500 Wire In Mumbai, Monel K500 Wire Exporters In Mumbai, Monel K500 Wire Suppliers In Mumbai, Monel K500 Wire Importers In Mumbai, Monel K500 Wire Stockists In Mumbai

Monel K500 Wire In India, Monel K500 Wire Exporters In India, Monel K500 Wire Suppliers In India, Monel K500 Wire Importers In India, Monel K500 Wire Stockists In India

Monel K500, K500 Monel Coil Wire, Alloy K500 Wire, K500 Monel Wire, ASTM B865 Monel Wire Suppliers And Exporters In Mumbai, India. Monel WERKSTOFF NR. 2.4375 Wire, Monel UNS N05500 Bright Wire, Exporters Of ASTM SB865 K500 Monel Wire In India. ASME SB865 Monel K500 Wire, K500 Monel Alloy Exporter, Monel K500 Wire Bobbin, Monel Alloy K500 Wire Rope, In India. Tig Wire Welding, Mig Wire Welding, Tig Welding Spool, Mig Welding Spool

- Domestic Area

- Our Export