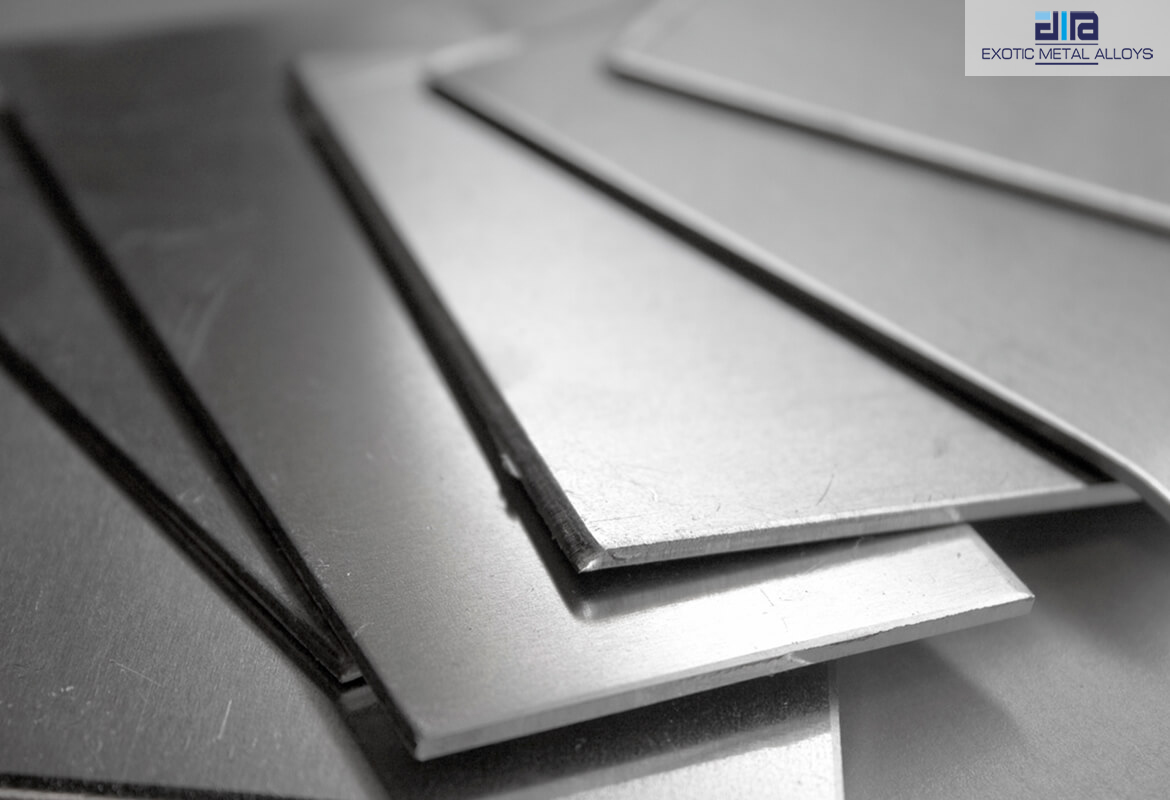

Nickel 201 Sheets & Plates

Nickel Alloy 201 Sheets Plates Coils, which limits trap from phosphoric harming and have been reasonably used with nitric ruinous. These Nickel 201 Plates is unaffected by any of the tricky bases, for instance, ammonium hydroxide, even in high obsessions and at high temperatures.

Our Nickel 201 Coils appeared to more grounded bases, for instance, sodium hydroxide at high obsessions and high temperatures will surely experience some cutting and breaking, especially with courses of action containing chlorides, for instance, sodium hypochlorite. Like steel, these Nickel 201 Slatting Coils is a reasonably poor channel of intensity, with in a general sense lower electrical conductivity than copper.

Various metals in contact with our Nickel 201 Perforated Coils, particularly in a sprinkled or acidic condition, may persevere through galvanic separating paying little regard to the way by which that the unadulterated metal may be unaffected. These Alloy 201 Sheets is dependably shielded to trap from acids, yet this quality depends upon the sort and centralization of the ruinous, the mixing temperature, and the sort of steel.

Our Alloy 201 Plates is impenetrable to sulphuric ruinous at room temperature, even in high focus interests. These Alloy 201 Coils are both important for confirming and coordinating acidic harming, especially in strategies where it is united with formic ruinous and when air spread is missing (oxygen guarantees steel under such conditions), at any rate it gives the best segment of security from use.

Specifications of Nickel 201 Sheets & Plates

| Specifications | : | ASTM / ASME SB 162 |

| Size | : | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | : | 0.1mm to 12 mm Thk |

| Form | : | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Finish | : | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | : | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 |

Chemical Composition Of Nickel 201 Sheets & Plates

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties Of Nickel 200 Sheets & Plates

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Other Types Of Nickel 200 Sheets & Plates

| N02201 Alloy Rolls | Nickel 201 Perforated Sheet | Nickel 201 Strip |

| Nickel 201 Hot Rolled Plate (HR) | Alloy 201 Cold Rolled Sheet (CR) | N02201 Alloy 201 Circle |

| Nickel 201 Sheets | Nickel 201 Plates | Nickel Alloy 201 Coils |

| Nickel Alloy 201 Shim Sheet | UNS N02201 Alloy Plate | Nickel 201 Flats |

| Alloy 201 Plain Sheet | 201 Nickel Blank (Circle) | 201 Alloy Foils |

| 201 Nickel Slatting Coil | DIN 2.4066 Alloy Thin Sheet | Nickel 201 Strips |

| UNS N02201 Alloy 201 Shim Sheet | Nickel 201 Polished Plates | Nickel Alloy 201 Polished Sheets |

Nickel 201 Sheets & Plates, Nickel 201 Sheets & Plates Exporters, Nickel 201 Sheets & Plates Suppliers, Nickel 201 Sheets & Plates Importers, Nickel 201 Sheets & Plates Stockists

Nickel 201 Sheets & Plates In Mumbai, Nickel 201 Sheets & Plates Exporters In Mumbai, Nickel 201 Sheets & Plates Suppliers In Mumbai, Nickel 201 Sheets & Plates Importers In Mumbai, Nickel 201 Sheets & Plates Stockists In Mumbai.

Nickel 201 Sheets & Plates In India, Nickel 201 Sheets & Plates Exporters In India, Nickel 201 Sheets & Plates Suppliers In India, Nickel 201 Sheets & Plates Importers In India, Nickel 201 Sheets & Plates Stockists In India

Nickel Alloy 201 Coils, Alloy 201 Sheets, Nickel UNS N02201 Plates, Nickel 201 Plates, JIS NW 2201 Plate, ASME SB 162 Nickel 201 Plate, Nickel Alloy 201 Circle, 201 Nickel Hot Rolled Plates Supplier in Mumbai, India. ASTM B 162 Nickel 201 Shim Sheets, 201 Nickel Plate Exporter, Nickel 201 Cold Rolled Plates, Nickel Werkstoff No 2.4068 Sheets, Nickel 201 Sheets Dealer in India. 201 Nickel Plate Stockholder, 201 Nickel Polished Cold Drawn Plates, Distributors Of ASME SB162 Nickel 201 Coils, Nickel 201 Slatting Coil, Nickel GOST НП-2 Strips Stockist, Manufacturer.

- Domestic Area

- Our Export