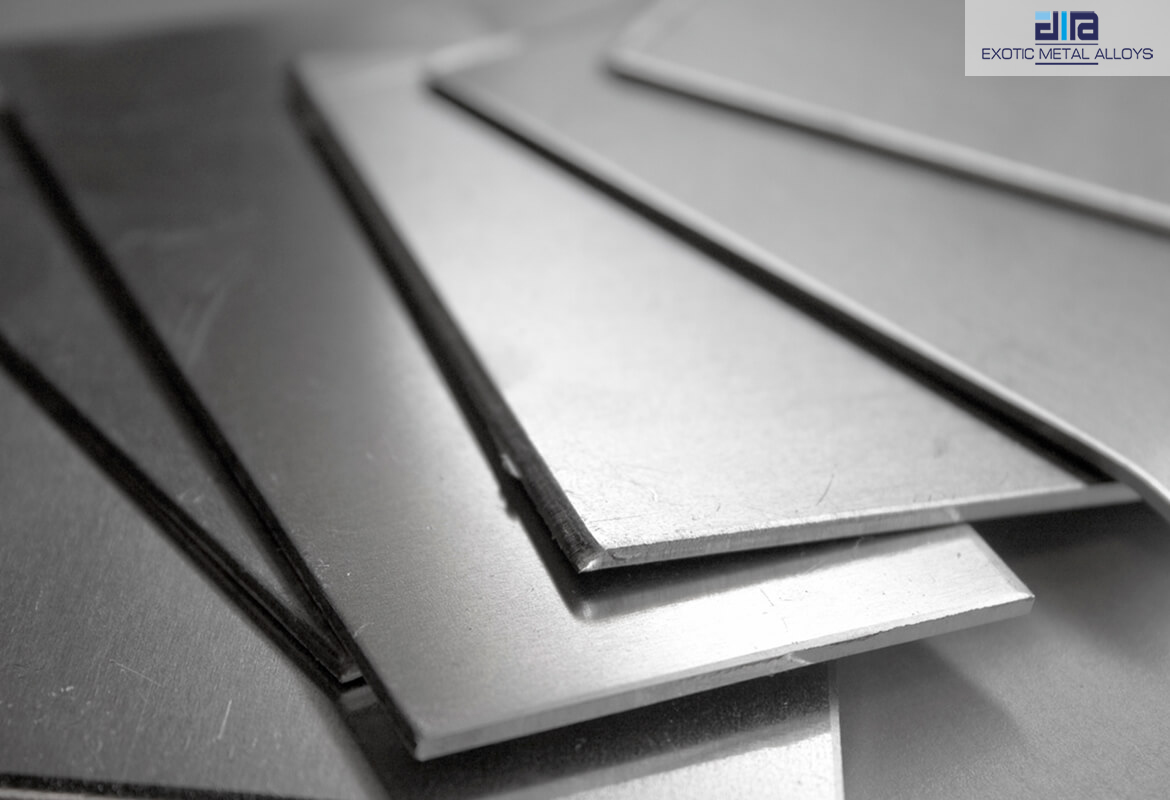

Incoloy 825 Sheets & Plates

Exotic Metal Alloys offers a broad assortment of Alloy 825 Sheets Plates and Coils, which are made by utilizing best nature of material. Uncompromising machining hardware and tooling must be utilized in these Incoloy 825 Slatting Coils to minimalize gab or work – hardening of the composite in front of the cutting. The degrees of copper and molybdenum empower our Incoloy 825 Perforated Coils to oppose diminishing acids and specialists.

Compound design of these Alloy 825 Plates offer extraordinary protection from a few destructive airs, for example, hole consumption, pitting, stress – erosion breaking and entomb – granular erosion. Compound 825 Coils is utilized in acceptable temperatures for around 1020 Degree F. In the mean time, Alloy 825 Slatting Coils are additionally being offered in various sizes and shapes to our clients.

These Alloy 825 Perforated Coils has great mechanical properties from moderate to high temperatures, where traditional machining procedures utilized for iron based combinations might be utilized. Incoloy UNS N08825 Sheets is particularly impervious to sulfuric and phosphoric acids, which further has great mechanical execution in both room temperature and up to 550 Degree C.

These Incoloy 825 Sheets is settled tempered at the factory to oppose bury – granular consumption as – welded, where tooling ought to be, for example, to take into consideration liberal clearances and radii. The extraordinary property of Nickel-Alloy 825 Coils is its consumption opposition. We likewise offer these Nickel-Alloy 825 Plates in most ideal costs.

Specifications of Incoloy 825 Sheets & Plates

| Specifications | : | ASTM / ASME SB 424 |

| Size | : | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | : | 0.1mm to 12 mm Thk |

| Form | : | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Finish | : | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | : | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Standard | Incoloy 825 |

| UNS | N08825 |

| GOST | ЭП703 |

| AFNOR | NFE30C20DUM |

| WERKSTOFF NR. | 2.4858 |

| BS | NA 16 |

| JIS | NCF 825 |

| EN | NiCr21Mo |

| OR | XH38BT |

Chemical Composition Of Incoloy 825 Sheets & Plates

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 825 | 0.05 max | 1.00 max | 0.5 max | 0.03 max | 1.50 – 3.00 | 22.00 min | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 |

Mechanical Properties Of Incoloy 825 Sheets & Plates

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 825 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Other Types Of Incoloy 825 Sheets & Plates

| Incoloy 825 Hot Rolled Plate (HR) | Alloy 825 Cold Rolled Sheet (CR) | N08825 Alloy 825 Circle |

| N08825 Alloy Rolls | Incoloy 825 Perforated Sheet | Incoloy 825 Strip |

| 825 Incoloy Slatting Coil | DIN 1.4958 Alloy Thin Sheet | Incoloy 825 Strips |

| Incoloy Alloy 825 Shim Sheet | UNS N08825 Alloy Plate | Incoloy 825 Flats |

| Alloy 825 Plain Sheet | 825 Incoloy Blank (Circle) | 825 Alloy Foils |

| Incoloy 825 Sheets | Incoloy 825 Plates | Incoloy Alloy 825 Coils |

| UNS N08825 Alloy 825 Shim Sheet | Incoloy 825 Polished Plates | Incoloy Alloy 825 Polished Sheets |

Incoloy 825 Sheets & Plates, Incoloy 825 Sheets & Plates Exporters, Incoloy 825 Sheets & Plates Suppliers, Incoloy 825 Sheets & Plates Importers, Incoloy 825 Sheets & Plates Stockists

Incoloy 825 Sheets & Plates In Mumbai, Incoloy 825 Sheets & Plates Exporters In Mumbai, Incoloy 825 Sheets & Plates Suppliers In Mumbai, Incoloy 825 Sheets & Plates Importers In Mumbai, Incoloy 825 Sheets & Plates Stockists In Mumbai

Incoloy 825 Sheets & Plates In India, Incoloy 825 Sheets & Plates Exporters In India, Incoloy 825 Sheets & Plates Suppliers In India, Incoloy 825 Sheets & Plates Importers In India, Incoloy 825 Sheets & Plates Stockists In India.

Incoloy 825 Perforated Sheet Suppliers, Alloy 825 Thin Sheet, DIN 1.4958 Incoloy 825 Plates, 825 Alloy Coils Distributors, Inconel 825 Plate, UNS N08825 Incoloy Alloy 825 Sheets Exporters in India.N08825 Incoloy Alloy 825 Strips, Incoloy 825 Shim Sheets Stockholders, Alloy 825 Plate, Alloy 825 Slatting Coil Dealers, Incoloy Ferrochronin 825 Plain Sheet Worldwide Exporters in India.Incoloy 825 Polished Plates, ASTM A168 Alloy 825 Incoloy Strips, Incoloy 825 Hot Rolled Plate (HR) Stockists, WNR 1.4958 Incoloy 825 Circle Suppliers, 825 Alloy Cold Rolled Sheet (CR) Dealers in India.

- Domestic Area

- Our Export